Case Study

Electrical Resistance Heating, Mertert (LU)

Location

Client

TEXACO

Scope

Regulatory clean-up

Texaco has chosen the Electrical Resistance Heating (ERH) technology for a regulatory clean-up at a full service retail station in Luxemburg. SPH could remediate the site in a short period without disrupting (24 hours) business or hindrance for customers.

BTEX was the contaminant of main concern at the site. Contamination was only present in the vadose zone as the watertable was at a depth of 12 meters. Maximum concentration of BTEX in the soil was some 340 ppm. Due to a sloping silt layer, contamination was present in vertical direction from 1 m-bg (East) and 7 m-bg (West) and between 3 m-bg (East) and 9 m-bg (West).

Cross-section sloped heating

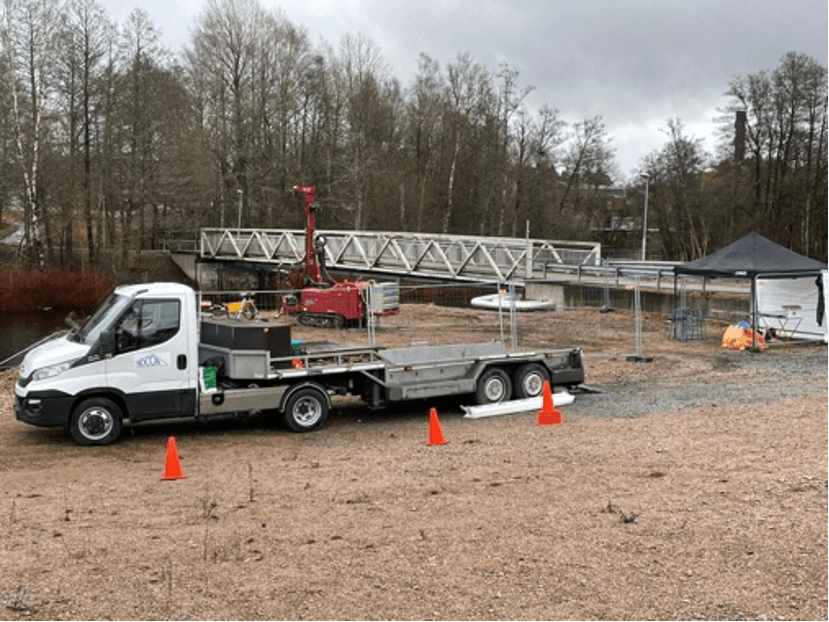

A surface area of approx. 150 m² was impacted. Soil volume, with BTEX concentrations exceeding the remediation goal of 10 ppm, was estimated at 350 m3. Installation was done in October 2004. After installing the subsurface cables, extraction hoses and a water drip system the site was paved with tarmac. As you can see, comparing both pictures the site owner directly took the opportunity to paint his shop. Electrodes were accessible by use of heavy-duty traffic manhole covers.

The heating system consisted of multiple ERH arrays, in total 13 electrodes were used. The exact depth of the conductive interval of 2 meters changed per electrode due to the tilted contaminated area. FOR temperature monitoring 3 thermowells were installed with 5 thermosensors each. After the subsurface installation was completed, system heating could start.

Field data, such as temperature and energy consumption, was collected by an on-site computer. This computer was equipped with a telemetry system and GPRS network connection. Via the GPRS connection data was transferred to the system operator in Holland. This data was regularly examined and if necessary, adjustments were made and sent back via the telemetry system to Luxembourg. After 12 weeks of heating the remediation goals were met and the site was declared clean.

This project offered us the opportunity to work on a design where the power distribution and the heating process were different because of the conductive intervals at varying depths. This design was equally as effective as standard electrode installations. The project was also our first complete vadose zone treatment. The water drip system controlled the water supply at electrode level and prevented the area from drying out (power failure). This was another successful international project with ERH remediation. The site owner experienced no inconvenience during the project and Texaco was pleased with the result and closed the lumpsum deal accordingly.