Case Study

Direct Push Injection, Bennebroek (NL)

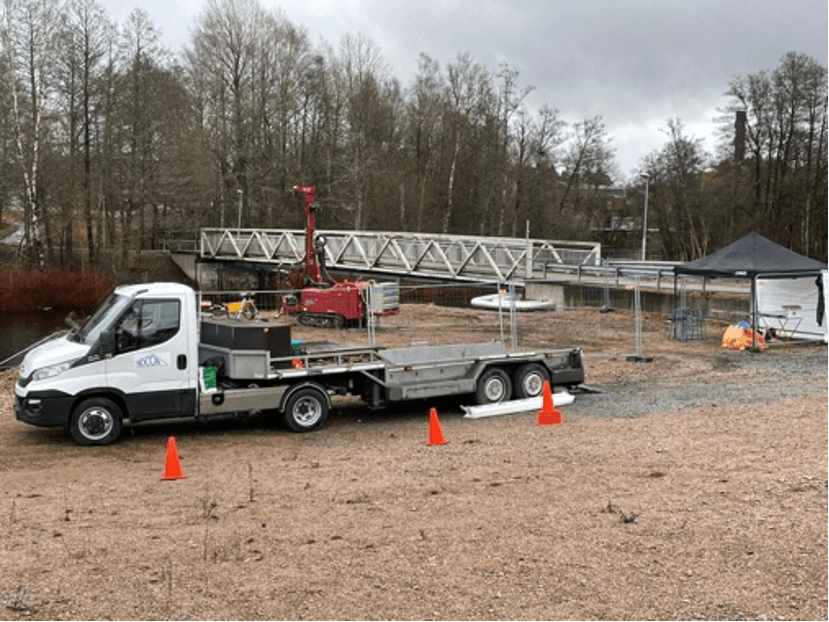

Location

Client

Unknown

Scope

Near a former woodshop creosote has seeped into the groundwater. The excavation was performed, followed by a period of groundwater abstraction. But monitoring learned that residual NAPL was present below the excavation depth. For this pump and treat wasn’t sufficient. Risk analysis showed that the current situation, after the initial remedial action, would allow future spatial development. But the client decided to take one more effort to remove as much mass as possible, with respect to the site’s characteristics.

SOME sort of chemical oxidation was required to remove the most volatile/mobile components within the creosote mixture. As the site is limited in its extent and in a residential, a low impact technique was favored. Fenton’s wasn’t desired as for the local situation, but the client decided to opt for the RegenOx™ product. RegenOx™ consists of two components. The first component is the oxidizer which contains sodium (per)carbonate. The other component is an activator (ferrous sulfate). The two components are shipped separately and require on-site mixing, just prior to injection.

In order to produce a stable solution and to maximize in-situ distribution the mixture is diluted to a 3-5% mixture. In this particular case surface water from a local canal was pumped to the site. Two injection rounds were anticipated and performed in September and December 2008. Initially, a strong concentration drop was seen, but some rebounds occurred. Most likely the injection and oxidation process forced residual NAPL from the pores and allowed it to solve in the groundwater.

It is anticipated that future monitoring will show a decline again as degradation and sorption will occur once ambient conditions are restored over time.