Case Study

Direct Push Injection, Oudenaarden (BE)

Location

Client

HRC advanced

Scope

Soil and groundwater were impacted with chlorinated solvents at a small industrial site in a residential area. Local authorities required remedial actions. Due to the local geology and the presence of several building structures, it was decided to clean the site via in-situ methods.

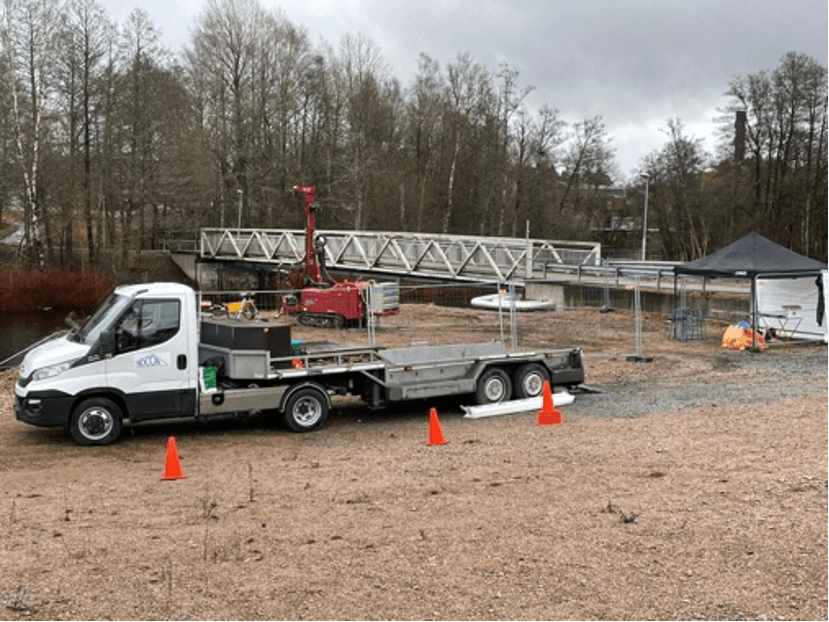

Tests with Regenesis HRC advanced were hopeful and there off it was decided to implement a small but full-scale approach. Within the contaminated zone 24 direct push injections were performed, where between 1 and 4 meters 400 liters per location was injected. Five (5) injections were performed between 1 and 8 meters, in which 700 liters per location were injected. Because of the geological setting injecting was performed top-down in order to maximize even distribution of the formula throughout the contaminated zone.

HRC advanced requires mixing with water. In this particular case, the “old formula” was selected, for which mixing with hot water was required. We used a steam pressure washer for hot water production. Four injection points were situated inside a workshop. Because of the relatively small but versatile 54DT machine, short maneuvering allowed injection in the relatively small space. Groundwater monitoring has to prove if the decay is sufficient or additional injection is needed.