Case Study

Electrical Resistance Heating, Ecclesfield (UK)

Location

Client

CL:AIRE

Scope

Introduction

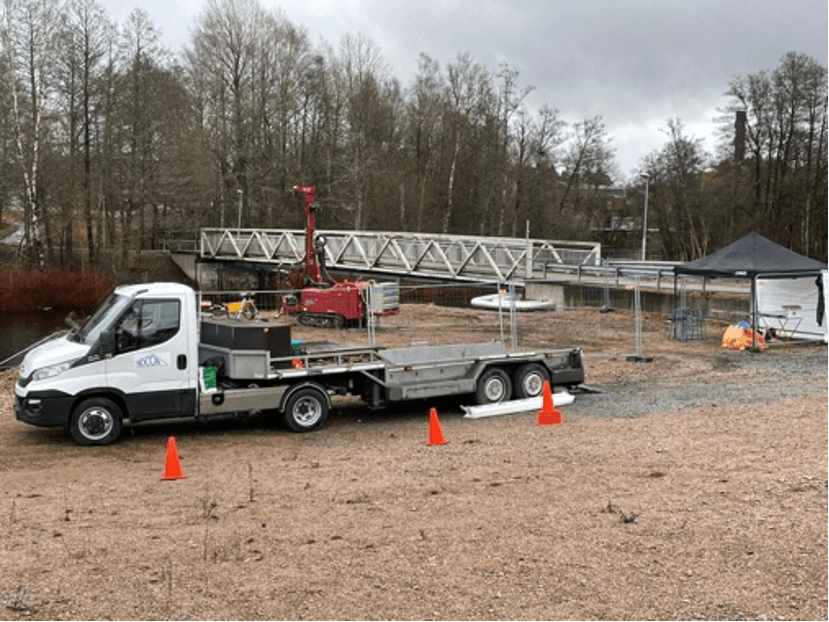

This bulletin describes the UK’s first use of Electrical Resistance Heating (ERH), an in situ electrical resistive heating technology, to mitigate the risk posed by historic contamination of the former tools manufacturing site in Sheffield by source removal. The demonstration has passed through CL:AIRE’s peer review system and is a CL:AIRE Technology Demonstration Project (TDP 26). Figure 1 shows part of the site during the demonstration with the installed electrode arrays, the extraction manifold, and equipment compounds.

Previous investigations at the two hectare site showed high levels of contamination, including dissolved, adsorbed and free phase chlorinated hydrocarbons, in heterogeneous cohesive soils and mudstone. The principal contaminants of concern driving the risk were:

- Trichloroethene (TCE) and vinyl chloride (VC) in the soil – human health risk; and

- TCE within the groundwater – environmental risk.

The key objectives of the demonstration were to:

- Extract contaminants from soil and groundwater to achieve a minimum concentration reduction in TCE of 80% in both phases, and a 50% VC reduction in the groundwater. The 80% TCE reduction was set due to being the equivalent of less than 1% of the TCE’s solubility limit;

- Achieve Site-Specific Acceptance Criteria (SSAC) values for key targeted contaminants to the satisfaction of the regulators;

- Undertake the active remediation within a 30 week overall project timeline period as agreed with the client; and

- Provide the entire process of remediation design, installation, activation, verification, decommissioning in a 43 week period to allow for site sign-off for residential redevelopment.

The bulletin describes why electrical resistive heating (in this case SPH) in combination with dual phase extraction was selected as the most appropriate technology for this site due to its combination of contaminants, geology and direct proximity to residential properties. This bulletin explains the background to the site, the technology evaluation and selection, the application of SPH and its performance against agreed project objectives.

Background to site

The two hectare site, located in Sheffield, close to the M1 motorway and in a densely populated area of residential properties, was formerly a tool manufacturing site where production had taken place for in excess of forty years. The site was acquired by Taylor Wimpey in early 2007 and proposed for residential redevelopment.

The site had been extensively sampled and two source areas of contamination were identified. Two significant investigations had been carried out on the site, in 1999 and 2004. The 1999 investigation included more than 75 window sampler locations, supplemented by 5 monitoring well installations. The 2004 investigation comprised 20 trial pits and a further 27 boreholes.

Site investigation information indicated an upper layer of Made Ground underlain by cohesive clays, silts and sands to between 3 and 4 m below ground level (bgl), over dense mudstone. Groundwater was generally recorded at between 3 and 4.1 m bgl. Chemical analysis of soils revealed two distinct hotspots of chlorinated hydrocarbons in the vicinity of the former manufacturing and storage areas, subsequently referred to as Source Area 1 and Source Area 2.

Contaminants of concern were identified as TCE and VC. Minor concentrations of other associated breakdown by-products were also recorded. A Detailed Quantitative Risk Assessment undertaken for the site highlighted potential risks to human health for the proposed future land use, which had to be mitigated to satisfy planning conditions.

The total volume of soils to be treated was approximately 3,500 m3 with the core area of each source area extending to 7 m bgl, within the mudstone. Approximately 630 m3 of groundwater was impacted. The source areas had been delineated by previous site investigation works using trial pits, probe holes and boreholes.